By Charles Ruban

The rapidly growing biotechnology and biopharmaceutical industries face environmental challenges from high energy use, material waste and carbon emissions the supply chain generates. Companies in this sector can promote ESG principles by adopting eco-friendly practices throughout production. This involves collaborating with vendors committed to sustainability across the supply chain. The industry should also prioritize investing in innovative technologies and renewables to minimize environmental impact.

The future of sustainable practices in the biotechnology and biopharmaceutical industry with a decarbonized supply chain

The global biotechnology and biopharmaceutical market has grown significantly in recent years and is expected to continue increasing in value, from an estimated $483 billion in 2024 to $546 billion in 2025, at a compound annual growth rate of 13% [1]. Currently, 4.4% of global carbon emissions are attributed to the healthcare sector, with approximately 71% of those emissions stemming from the supply chain [2]. As this sector grows and evolves, sustainability is becoming a critical focus. The industry is actively working to reduce its environmental impact while maintaining product quality and safety [3].

While investigating sustainable solutions, the sector still confronts considerable environmental challenges. The impact can vary significantly depending on the specific process, scale of operation and the technologies employed. Some of the most consequential contributors to bioprocessing environmental impact include:

The urgent need to maintain global temperature growth below 1.5°C to mitigate the worst impacts of climate change [4] means that the industry is stepping up its efforts to reduce carbon emissions. Many companies in this sector are setting ambitious targets to achieve net-zero emissions, adopting renewable energy sources and enhancing energy efficiency in their manufacturing processes and plant building.

Governments worldwide are implementing stricter environmental regulations, including carbon pricing and emissions targets. Decarbonization can drive innovation and create new business opportunities in renewable energy, energy efficiency and carbon capture technologies. The industry can reduce its carbon footprint and enhance its reputation and competitiveness by taking decisive action.

The widespread use of single-use (SU) bioprocessing components, such as bags, tubing and filters, generates substantial plastic waste. Although convenient, these disposable items may contribute to plastic pollution and environmental degradation. Bioprocessing uses large volumes of media and buffers, often containing chemicals that can affect the environment if not correctly disposed of. Spent cell culture media and other bioprocessing waste streams can contain nutrients and other compounds that contribute to water pollution if not treated appropriately.

Bioprocessing often involves rigorous sterilization and cleaning procedures, which can be energy-intensive, particularly when using traditional methods such as clean-in-place (CIP). Maintaining precise temperature control within bioreactors and throughout the process requires significant energy consumption, especially for cooling and heating large volumes. Depending on the nature and volume of the waste, treating wastewater generated by bioprocessing can also be energy-intensive.

Key players have invested in environmental, social and governance (ESG) principles to achieve sustainability in the biotechnology and biopharmaceutical industries. By prioritizing sustainability and ethical practices, these organizations can contribute to a healthier planet and drive positive social impact. This also allows investors to contribute to a more sustainable and equitable future while creating value for stakeholders.

Shared responsibility and supply chain impacts

Companies in this sector and their customers are jointly responsible for working toward sustainability, including minimizing their carbon footprint. A sizable portion of a company’s carbon footprint comes from its supply chain, which encompasses raw materials, transportation and vendors’ manufacturing processes. If vendors have high carbon emissions, their customers’ overall environmental impact is directly influenced.

Globally, increasingly stringent environmental regulations are being implemented, and customers may face penalties or even reputational damage if their supply chain contributes significantly to greenhouse gas emissions.

Although challenging, measuring the entire carbon footprint is the crucial first step in defining a decarbonization strategy for a company in this field. This comprehensive assessment allows the company to identify key areas of improvement, set realistic targets and implement effective measures to reduce its overall environmental impact.

By analyzing scope 1, 2 and 3 carbon emissions, companies can better understand and manage their overall environmental impact. This includes:

- Scope 1: Direct emissions the company produces from sources it owns or controls, such as on-site combustion, company-owned vehicles or fugitive emissions from production processes.

- Scope 2: Indirect emissions from purchased energy associated with generating electricity, heat or steam, such as emissions from the power plants that supply electricity to the company’s facilities.

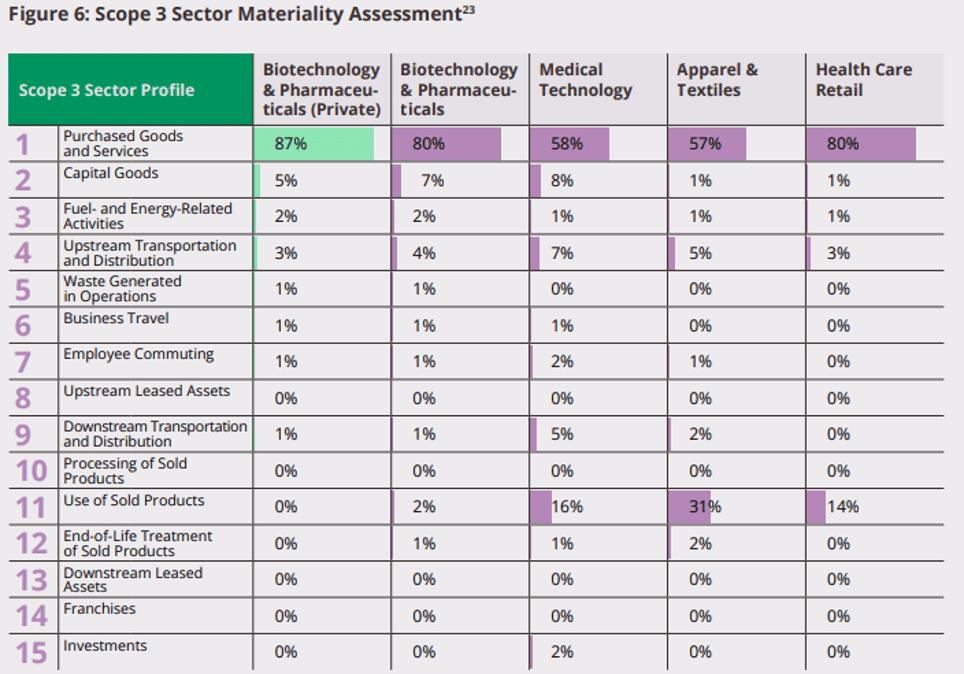

- Scope 3: All other indirect emissions across the company’s value chain, from the production and transportation of raw materials, purchased goods and services, and emissions from the transportation and distribution of the company’s products, as well as their use and disposal by customers. Overall, scope 3 emissions represent over 85% of the world’s overall footprint.

Companies should require all third-party vendors, whether raw materials, consumables, service providers or equipment vendors, to provide systematic calculations.

Responsible bioprocessing approaches to reduce carbon footprints

Companies in the sector can significantly reduce their carbon footprints by adopting energy-efficient manufacturing processes. This includes streamlining production steps to minimize energy consumption, implementing heat recovery systems to capture and reuse heat waste and optimizing temperature control systems. Investing in renewable resources is also crucial and may involve installing on-site energy sources such as solar panels and wind turbines and exploring alternative energy sources like geothermal energy and biogas.

Making eco-friendly equipment choices can significantly impact companies’ carbon footprint. Investing in high-efficiency bioreactors, energy-efficient filtration systems and automated process control technologies can substantially reduce energy consumption and improve overall efficiency.

Another crucial step in reducing one’s carbon footprint is minimizing the use of consumables. This can involve optimizing processes to reduce material waste, cell culture media and buffers. Prioritizing suppliers that share a commitment to sustainable practices further amplifies these efforts.

Finally, evaluating and optimizing the carbon footprint of manufacturing plants, including bioproduction equipment, building materials, transportation and construction activities, is essential for minimizing the environmental impact of capital investments.

The importance of carbon offsetting and data transparency

Biotechnology and biopharmaceutical companies and their vendors can take a proactive step toward sustainability by offsetting all residual carbon emissions through verified carbon credits. This positive action not only neutralizes emissions but also supports impactful environmental projects worldwide, such as afforestation and renewable energy initiatives. By offsetting, companies demonstrate their commitment to a greener future and contribute to global environmental well-being.

When developing a carbon offsetting strategy, companies must select credible offset providers and ensure projects are certified and aligned with recognized standards. Responsible providers, like those operating under the French Bas-Carbone Label, integrate offsetting with sustainability goals. As regulations tighten and stakeholders demand greater environmental accountability, companies will need to integrate offsetting with innovative technologies and broader sustainability initiatives.

Transparency is key to effectively managing the carbon footprint in companies’ supply chains. To achieve this, vendors should be prepared to share their emissions data with customers openly. This enables companies to accurately assess the overall environmental impact of their supply chain and collaborate with vendors to develop and implement effective reduction strategies. Independent third-party verification of this data further enhances credibility and strengthens sustainability claims.

Toward a sustainable future of the biotechnology and biopharmaceutical industry

To reduce its environmental impact, the industry must prioritize sustainable innovation, encompassing the development and implementation of green chemistry principles, biocatalysis and a circular economy approach. Reducing energy intensity can be achieved through renewable energy adoption and using energy-efficient equipment. Waste minimization strategies that companies should consider include minimizing material waste, implementing robust waste management systems and exploring waste-to-energy technologies. Advancements in purification technologies, such as continuous processing, membrane-based technologies and process analytical technologies (PAT), have helped companies in the sector significantly improve efficiency, reduce waste and minimize environmental impact. This rapidly growing and evolving industry can contribute to a more sustainable future by focusing on these areas.

About the Author

With nearly 30 years of international experience, Charles Ruban is a seasoned executive in the biopharmaceutical and medical industries. Before joining Verdot, he was the Deputy CEO of HTL Biotechnology, the COO of DBV Technologies and an executive at Stallergenes. He has launched biologics in markets such as Europe, the US and Japan. In addition to his professional achievements, Charles is committed to carbon footprint reduction initiatives and is a member of the Citizens’ Climate Lobby.

With nearly 30 years of international experience, Charles Ruban is a seasoned executive in the biopharmaceutical and medical industries. Before joining Verdot, he was the Deputy CEO of HTL Biotechnology, the COO of DBV Technologies and an executive at Stallergenes. He has launched biologics in markets such as Europe, the US and Japan. In addition to his professional achievements, Charles is committed to carbon footprint reduction initiatives and is a member of the Citizens’ Climate Lobby.

References

- https://www.prnewswire.com/news-releases/global-biotechnology-market-outlook-2025-driving-growth-at-13-0-cagr–marketsandmarkets-302346776.html

- https://www.ispor.org/docs/default-source/intl2023/ispor23dehipawalaposter-pdf.pdf?

- https://www.bioindustry.org/resource-report/sustainability-in-action-how-bioprocessing-is-pioneering-sustainable-practices.html

- https://www.climate.gov/news-features/features/whats-number-meaning-15-c-climate-threshold

#ESG #Investing #Trends #Shaping #Future